Product Description

Model NO.: JMT-1200FT

Usage: Environmental Protection

Style: Tube

Certification: CE

Working Temperature: 5-50centidegree

Distributor Power: 110V/AC,60Hz;220V/AC,50Hz

Control Source: Gas or Liquid

Controller Shell Size: 290*190*140mm

Brand: Jieming

Specification: CE

HS Code: 84212990

Type: Activated Carbon

Motive Force: Pressure

Performance: Efficient Filtration

Working Pressure: 0.2-0.6MPa

Raw Water Hardness Requiement: Less Than 8mmol/L

Controller Power, Frequency: 85-220V/AC,50/60Hz,4W

Distributor Connection Method: Fast-Inserting Joint

Language: Chinese/ English

Trademark: JIEMING

Origin: China

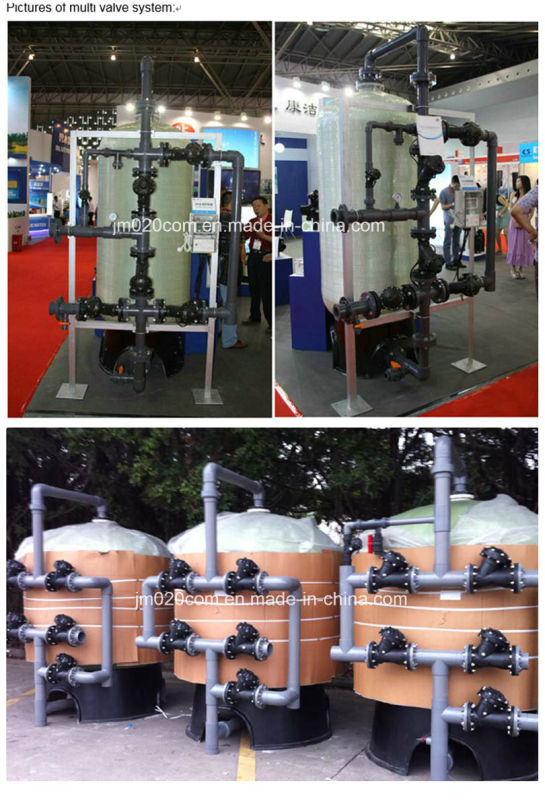

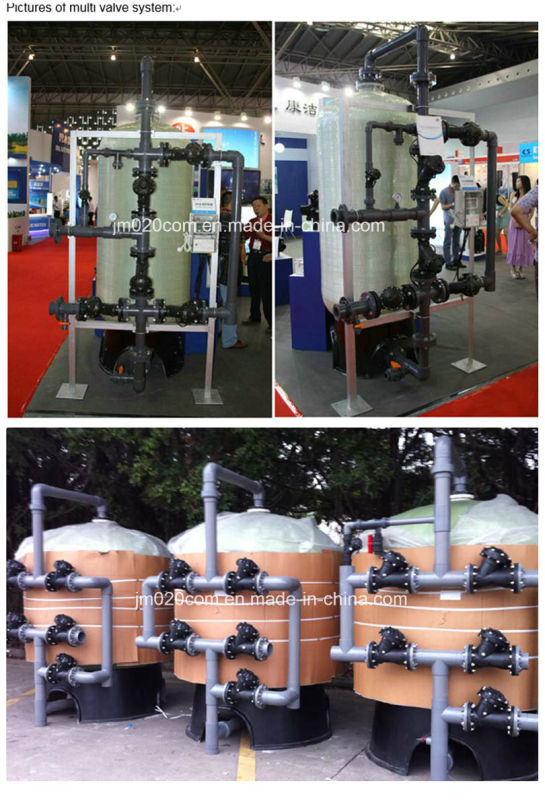

Automatic Multi Valves Water Filter System for Water Treatment

Characteristics

Stager Controller of Multivalve Water Filter system:

>> Language selection: Chinese and English, Operation adjustment

>> Power adapter, frequency, power: 85-250V/AV, 50/60HZ, 4W

>> Control source: Gas or liquid (advised plus 100UM pre filter)

>> Pressure of control source: 0.2MPA-0.8MPA

>> Distributor connection method: fast-inserting joint

>> Working environment temperature:4-60ºC

>> The controller shell size: 290*190*140mm

1. The main difference between multivalve system and multi ports valve system:

1.1 After more than ten years` popularization and application of the automatic multi-ports valve in our country. The operation control mode of softening water equipment in our country has generally changed from the origin valve control. However, the multi-ports valve still has some limitations, because of its own high integration, small caliber, complex structure etc., especially when the running condition requirements of a complex system application.

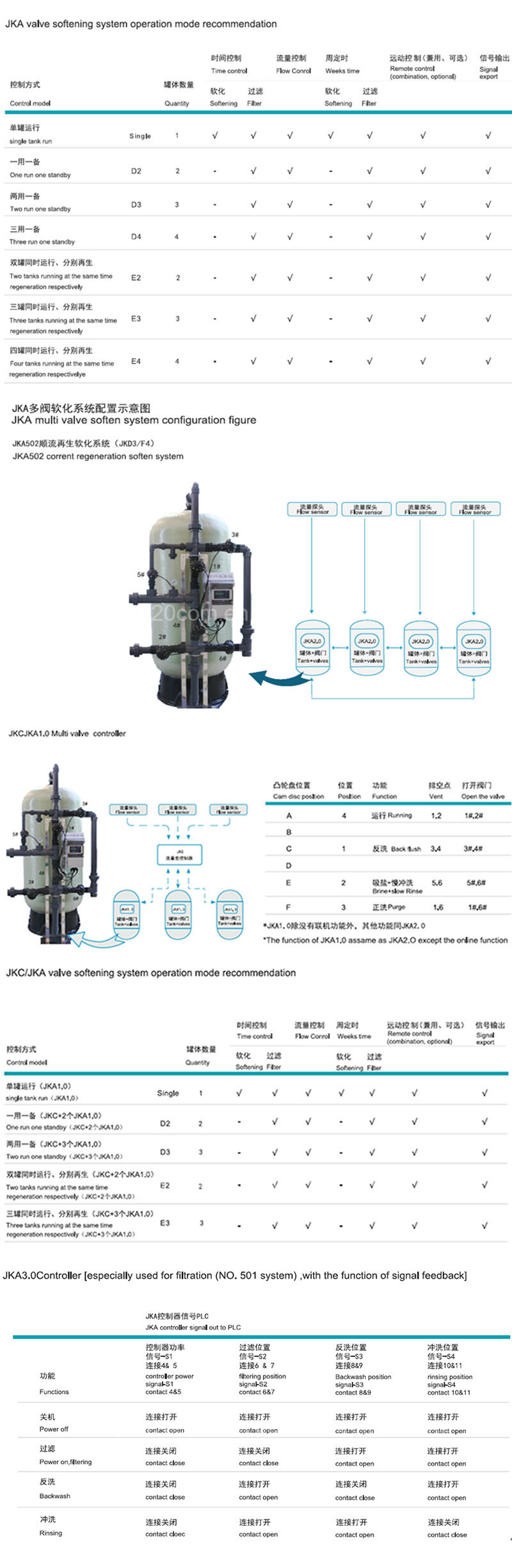

1.2 The JK mode automatic multivalve softener has made up for the deficiency of the multi-port valve system. The following table lists include main difference and characteristics between multivalve and multi- ports valve.

1.3 JKA series valve controller after more than ten years development, the application in the electric power, petrochemical, chemical, filtration, softening of central heating and many other industries, such as oxygen, iron fierce water treatment engineering, get the high praise from water treatment industry people and general customers. We actively respond to market demand, on the basis of the original JKA controller, we develop JKA series valve controller.

1.4 JKA2.0 series multivalve controllers JKA2.0 series valve controller on the basis of original more expanded to four sets running at the same time, greatly improving the system water capacity, better adapt to the large system water demand, providing reasonable and effective control system, stable, simple, economic and practical for water treatment engineering company.

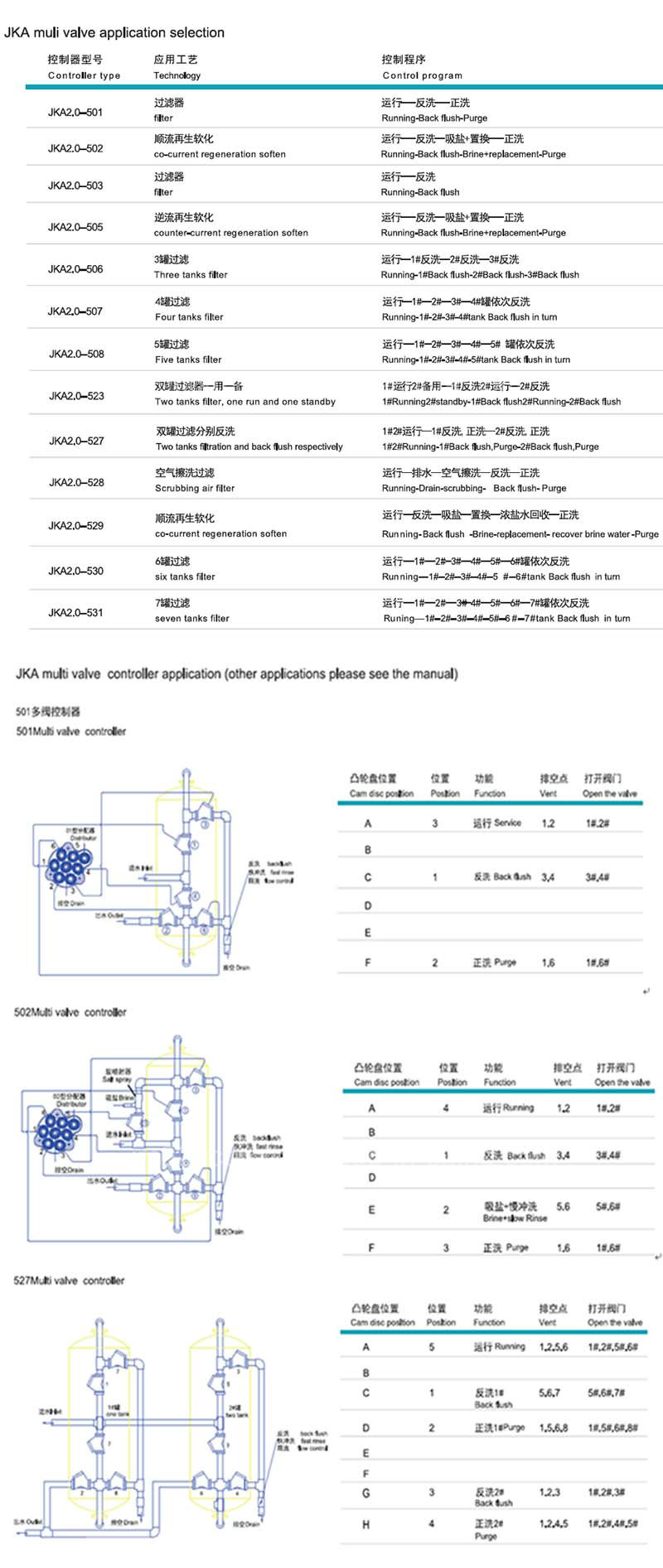

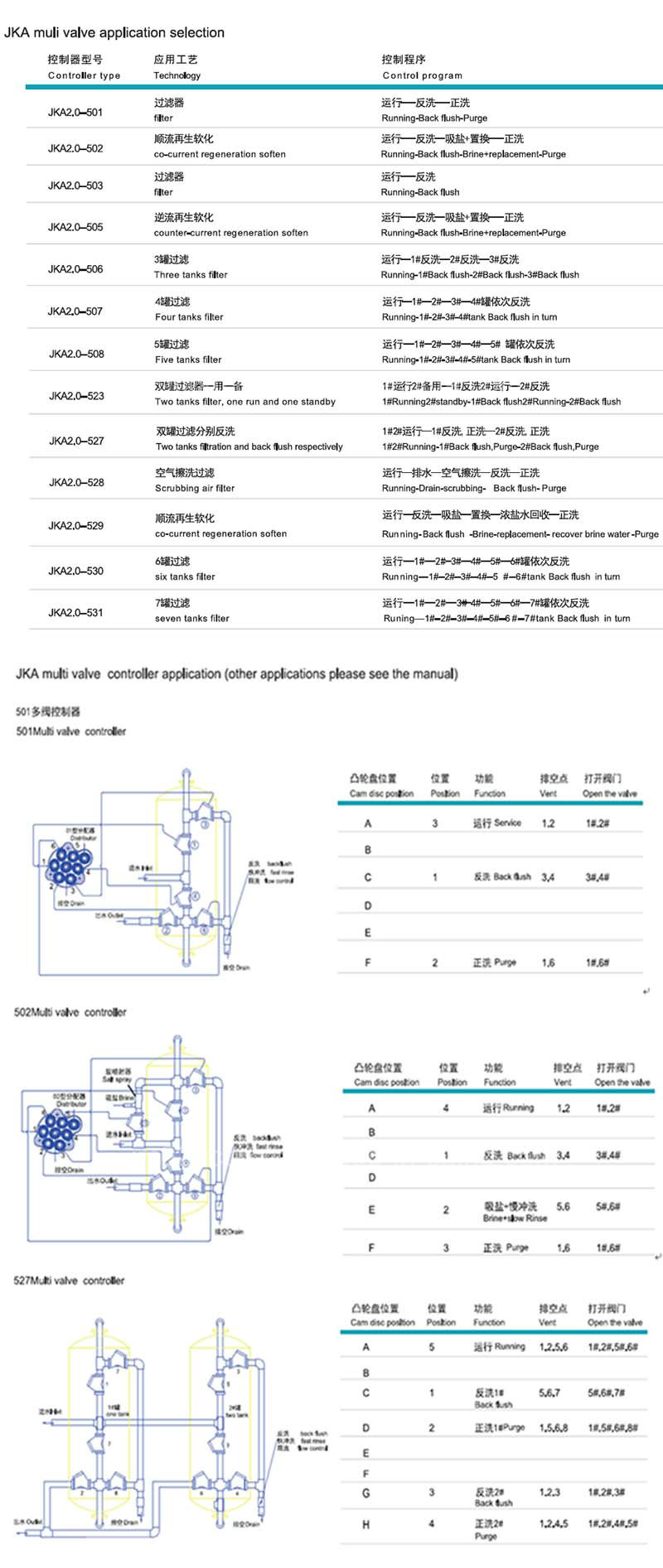

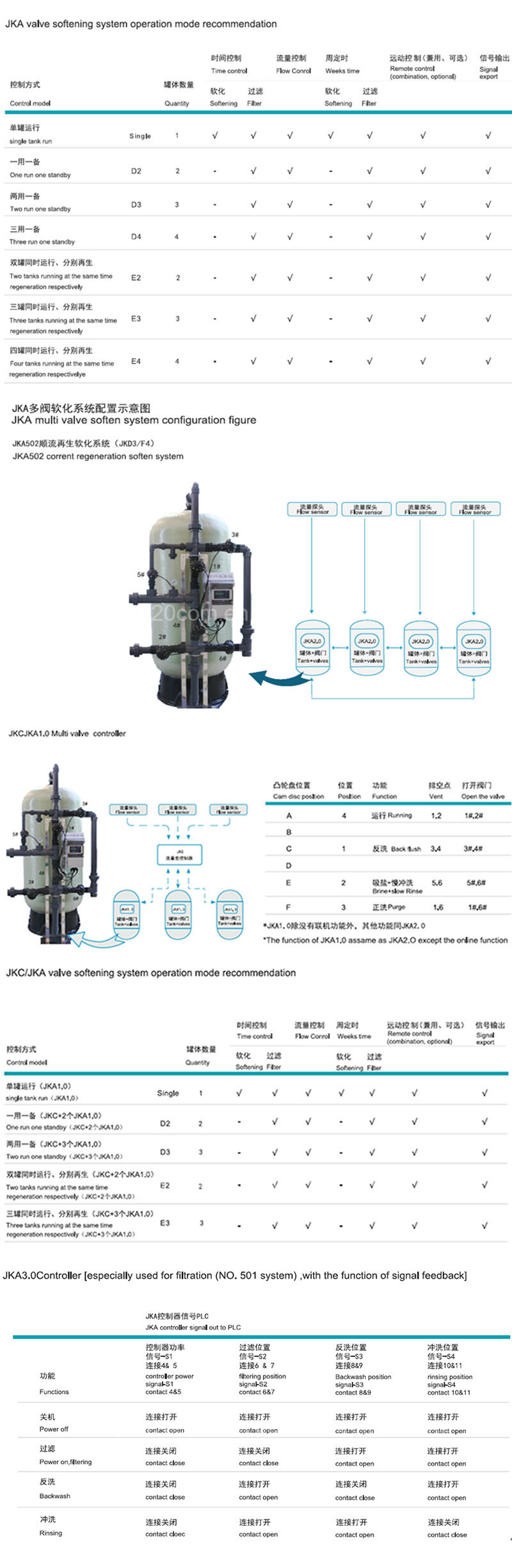

Multivalve filter system Model selection table ( only for reference):

| NO. | Activated filter | Flow rate | Description ( Details) | Spec. | Q'ty | Unit | Remark |

| Model | T/H |

| 1 | JMT-750FT | 6-8T/H | 1. Frp Tank (150PSI) | φ750×1850-4"top-4" bottom, 30"*72" | 1 | pc | SINGLE TANK / TIMMER |

| 2. Top & botton strainers | Adated for tank φ750×1850-4"top-4" bottom | 1 | set |

| 3. Y Pattern Diaphragm Valve | DN40 | 5 | pc |

| 4. JMA controller | JMA501 | 1 | pc |

| 5. Coconut Activated carbon | 25 kgs/bag, 8-16 mesh | 10 | bag |

| 6. Pipes | UPVC | 1 | batch |

| | | | | | | | |

| 2 | JMT-900FT | 8-10T/H | 1. FRP Tank (150PSI) | φ900×1850-4"top-4" bottom, 36"*72" | 1 | pc | SINGLE TANK / TIMMER |

| 2. Top & botton strainers | Adated for tank φ900×1850-4"top-4" bottom | 1 | set |

| 3. Y Pattern Diaphragm Valve | DN50 | 5 | pc |

| 4. JMA controller | JMA501 | 1 | pc |

| 5. Coconut Activated carbon | 25 kgs/bag, 8-16 mesh | 13 | bag |

| 6. Pipes | UPVC | 1 | batch |

| | | | | | | | |

| 3 | JMT-900FT-H | 8-10T/H | 1. FRP TANK(150PSI) | φ900×2400-6"F-6"F, 36"*94" | 1 | pc | SINGLE TANK / TIMMER |

| 2. Top & botton strainers | Adated for tank φ900×2400-6"F-6"F, 36"*72" | 1 | set |

| 3. Y pattern diaphragm valve | DN50 | 5 | pc |

| 4. JMA controller | JMA501 | 1 | pc |

| 5. Coconut Activated carbon | 25 kgs/bag, 8-16 mesh | 17 | bag |

| 6. Pipes | UPVC | 1 | batch |

| | | | | | | | |

| 4 | JMT-1000FT | 10-14T/H | 1. FRP TANK(150PSI) | φ1000×1850-4"top-4" bottom, 40"*72" | 1 | pc | SINGLE TANK / TIMMER |

| 2. Top & botton strainers | Adated for tank φ1000×1850-4"top-4" bottom | 1 | set |

| 3. Y pattern diaphragm valve | DN50 | 5 | pc |

| 4. JMA controller | JMA501 | 1 | pc |

| 5. Coconut Activated carbon | 25 kgs/bag, 8-16 mesh | 16 | bag |

| 6. Pipes | UPVC | 1 | batch |

| | | | | | | | |

| 5 | JMT-1000FT-H | 10-14T/H | 1. FRP TANK(150PSI) | φ1000×2400--6"F-6"F, 40"*94" | 1 | pc | SINGLE TANK / TIMMER |

| 2. Top & botton strainers | Adated for tank φ1000×2400--6"F-6"F | 1 | set |

| 3. Y pattern diaphragm valve | DN50 | 5 | pc |

| 4. JMA controller | JMA501 | 1 | pc |

| 5. Coconut Activated carbon | 25 kgs/bag, 8-16 mesh | 20 | bag |

| 6. Pipes | UPVC | 1 | batch |

| | | | | | | | |

| 6 | JMT-1200FT | 14-20T/H | 1. FRP TANK(150PSI) | φ1200×1850---6"F-6"F, 48"*72" | 1 | pc | SINGLE TANK / TIMMER |

| 2. Top & botton strainers | Adated for tank φ1200×1850---6"F-6"F | 1 | set |

| 3. Y pattern diaphragm valve | DN65 | 5 | pc |

| 4. JMA controller | JMA501 | 1 | pc |

| 5. Coconut Activated carbon | 25 kgs/bag, 8-16 mesh | 18 | bag |

| 6. Pipes | UPVC | 1 | batch |

| | | | | | | | |

| 7 | JMT-1200FT-H | 14-20T/H | 1. FRP TANK(150PSI) | φ1200×2400--6"F-6"F, 48"*94" | 1 | pc | SINGLE TANK / TIMMER |

| 2. Top & botton strainers | Adated for tank φ1200×2400---6"F-6"F | 1 | set |

| 3. Y pattern diaphragm valve | DN65 | 5 | pc |

| 4. JMA controller | JMA501 | 1 | pc |

| 5. Coconut Activated carbon | 25 kgs/bag, 8-16 mesh | 28 | bag |

| 6. Pipes | UPVC | 1 | batch |

| | | | | | | | |

| 8 | JMT-1500FT | 20-30T/H | 1. FRP TANK(150PSI) | φ1500×1850--6"F-6"F, 60"*83" | 1 | pc | SINGLE TANK / TIMMER |

| 2. Top & botton strainers | Adated for tank φ1500×1850--6"F-6" | 1 | set |

| 3. Y pattern diaphragm valve | DN80 | 5 | pc |

| 4. JMA controller | JMA501 | 1 | pc |

| 5. Coconut Activated carbon | 25 kgs/bag, 8-16 mesh | 36 | bag |

| 6. Pipes | UPVC | 1 | batch |

| | | | | | | | |

| 9 | JMT-1500FT-H | 20-30T/H | 1. FRP TANK(150PSI) | φ1500×2400--6"F-6"F, 60"*83" | 1 | pc | SINGLE TANK / TIMMER |

| 2. Top & botton strainers | Adated for tank φ1500×2400--6"F-6" | 1 | set |

| 3. Y pattern diaphragm valve | DN80 | 5 | pc |

| 4. JMA controller | JMA501 | 1 | pc |

| 5. Coconut Activated carbon | 25 kgs/bag, 8-16 mesh | 40 | bag |

| 6. Pipes | UPVC | 1 | batch |

| | | | | | | | |

| 10 | JMT-1800FT | 30-40T/H | 1. FRP TANK(150PSI) | φ1800×2400--6"F-6"F, 72"*94" | 1 | pc | SINGLE TANK / TIMMER |

| 2. Top & botton strainers | Adated for tank φ1800×2400--6"F-6"F | 1 | set |

| 3. Y pattern diaphragm valve | DN100 | 5 | pc |

| 4. JMA controller | JMA501 | 1 | pc |

| 5. Coconut Activated carbon | 25 kgs/bag, 8-16 mesh | 54 | bag |

| 6. Pipes | UPVC | 1 | batch |

About us:

Guangzhou Jieming

Water Treatment Equipment Co., Ltd.is dedicated to the development of water treatment in Southeast Asia. We have adopted advanced water treatment technology in Europe and America for industrial water treatment, pure water, drinking water, ion exchange systems, Reverse Osmosis systems, ultrafiltration systems, and undertake all types of water treatment works.

We have our own factory to produce tank FRP, Disc Filter , reverse osmosis

Water Treatment Plant,

Multi Valve System. We are also the agents of all kinds of water treatment components, such as Y pattern diaphragm valve, Backwash Valve , Fleck Valve , Runxin valve, Fobrite valve, FRP and

Stainless Steel Membrane Housing, PVC Bag Filter ,

PVC Cartridge Filter, distributors, brine valve, brine tank, water tank...etc. You can achieve a one-stop purchase here, saving time, energy and money.

FAQ

1. Are you the manufacturer?

Yes, we can make the whole multivalve system.

2. How to package and ship them.

It depends on customer`s requirements. We can package them in separate parts, and it is also no problem for us to assemble the pipelines for you.

3. What`s the payment terms?

Prepaid 30% BY T/T as the deposit, 70% the balance by T/T before delivery.

4. Can you arrange the shipping for us?

Of course we can.

5. Do you have other parts for water treatment?

Yes, other products please check our websites.

6. What other service can you offer?

Besides the technical support, we can also help you to collect other water treatment products, and ship all of your goods together.

Contact us if you need more details on Filter System. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Filter、Water Treatment. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Water Treatment Plant > Multi-valve Filter/ Softener System